Introduction:

technology and the development of a new, multifunction and multipurpose

industrial

pump.It completely out of the running mode of traditional pump

impeller and shaft seal and impurities on the viscosity, corrosive, fluid medium

transport has a great advantage, using the principle of very different from the

traditional pump, wide application range.

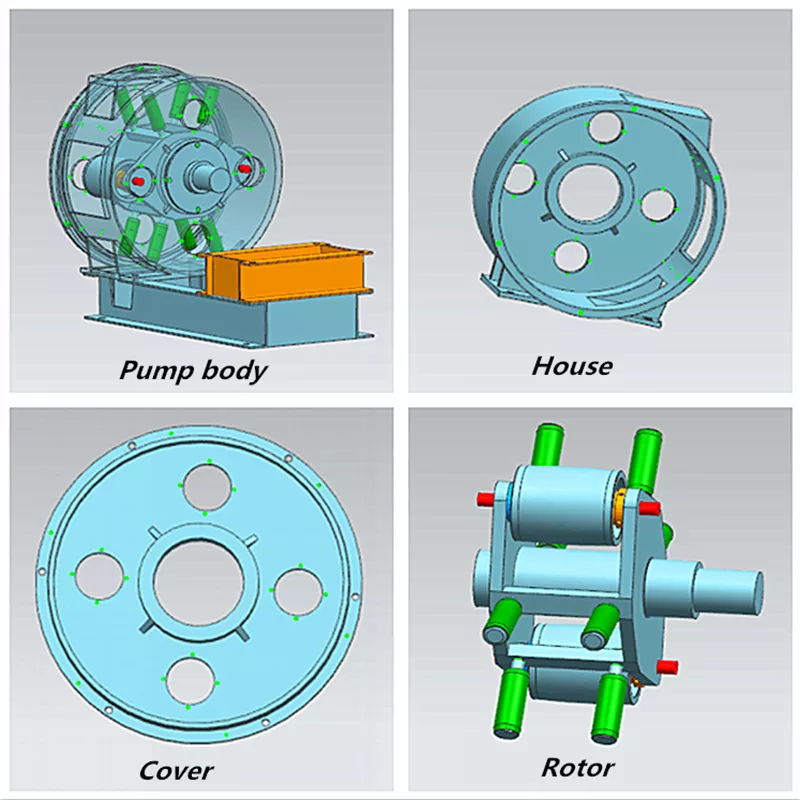

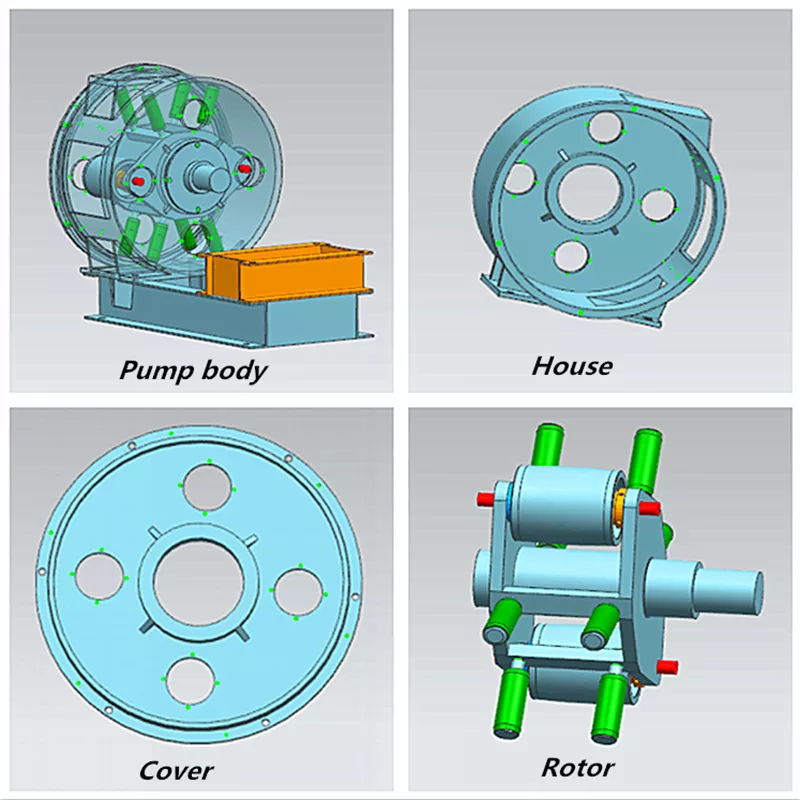

Pump in the form of the structure: vertical, horizontal pump.

Pump into the form of the hose: single pipe pump, double pump.

Pump according to the sealing form is divided into: No Sealed Structure

Feature and use:

1. Unique without sealing structure make it won't create any leaks;

2. Strong self-priming capacity, water absorption can reach 8 meters;

3. The pump suction fluid contact with rubber hose, only thus can transport all

kinds of viscosity, density, corrosion resistance, abrasive fluid material;

4. Can deliver a solid particles, crystals, fiber material and other impurity liquid

materials, won't produce any blockage and fault;

5. Can be positive and negative to work, with self-cleaning ability;

6. Do not need irrigation pump pump start-up, operation especially convenient

for clearance;

7. The vibration and noise is small, can be fixed on the trolley mobile operation;

8. Simple structure, convenient operation and maintenance;

9. Less power consumption, high volumetric efficiency, and has good

measurement capability.

Areas of application:

1. The chemical industry: acid, alkali, phosphate slurry and inorganic materials

such as titanium dioxide;

2. Petrochemical: drilling mud and previous delivery;

3. Water treatment: silt mud, lime etc;

4, mining, metallurgical industry, gold mining, gold smelting of filling materials

in the pulp in the process of the transportation;

5. The pharmaceutical industry: all kinds of material liquid drug delivery;

6. The food industry: oil material and beverage conveying;

7. Paper industry: pulp, sulphur pulp conveying;

8. The construction industry: cement mortar conveying;

9 in ceramic industry, ceramic glaze slurry etc;

10. Nuclear waste, electrolytic slag, slag metal liquid, paint, coatings,

adhesives, glue, rubber latex, refractory fiber pulp and all other tightly seal

requirements, more liquid viscosity, particle content delivery.

Operating principle:

A wall smooth, reliable strength of special rubber hose inside the pump

installation, by rotating the squeezing roller along the hose is a pair of such

rotation makes medium to one direction, and there won't be back.Flattened

hose under their own flexibility and side guide roller forced restorable. At this

point, the tube materials materials will produce high vacuum suction cavity,

and then, the material in the subsequent roller pressure escape from the

hose.So the cycle, material overtaken by suction and discharge.

Hose has the characteristics of long service life, wide applicable scope, it is the

structure of the strengthen of layer or one multilayer high strength synthetic

fiber braid.Hose lining and outer lining extrusion, lined with adopting a series of

compound rubber.The tube body soft, rich in high strength elasticity, has

superior wear resistance.Synthetic fiber is added to the hose body, enhance

the overall performance of the pipe body.Heat production is low, in use process

good elastic resilience, durable.Hose has good resistance to positive pressure

and negative pressure, has the good characteristics of acid, alkali, oil, high

temperature, can be more than 90% of the chemicals today.Main ingredients

are natural rubber (generally weak acid and alcohol resistance), butyl rubber

(oil resistance, alkali and detergents, etc.) and EPDM (applicable to ketone,

alcohol and concentrated acid), etc.Hose using temperature is 100 ℃ or less

and produces heat in the process of production, is generally used in medium

temperature < 80 ℃ condition.If the ventilation (or cooling) cooling condition

good cases, medium temperature can reach 100 ℃.If the material

temperature > 100 ℃, need to use special heat resistant hose.Have health

level medium (such as food, medicine, etc.), can use special health level of the

hose.The other can according to user need for non-standard design.